Four CES announcements show Qualcomm pushing the same idea across categories: move more AI and control loops onto efficient, tightly integrated edge platforms.

Qualcomm used CES 2026 in Las Vegas to lay out a familiar theme in three very different markets: higher local compute density, more on-device AI, and fewer chips and boxes around the main silicon.

On the PC side, this appears as a new Snapdragon X Series option designed for professionals and aspiring creators. In robotics, it is a full-stack architecture paired with a processor roadmap designed to move humanoids and industrial autonomous mobile robots closer to deployment. In the automotive industry, it represents another step away from distributed ECUs toward centralized domain computing, with a Leapmotor controller that combines cockpit and driver-assistance workloads on a dual-chip platform.

Snapdragon X2 Plus for AI Workloads

Snapdragon X2 Plus slots into Qualcomm’s Windows 11 Copilot+ PC push with a straightforward promise: maintaining the “thin-and-light” behavior people associate with mobile silicon while adding enough AI throughput to make local workflows feel normal rather than a novelty. Qualcomm is pairing a 3rd Gen Oryon CPU with an on-die Hexagon NPU rated at 80 TOPS, plus Wi-Fi 7 and optional 5G. Systems built on the platform will be delivered by major OEMs in the first half of 2026.

Snapdragon X2 Plus.

The key detail here is that the AI block is not treated as a nice-to-have add-on. Rather, Qualcomm is explicitly pitching the NPU as an always-on compute resource for next-gen AI features, which is important for creator workloads that increasingly mix classic compute with model workloads such as transcription, denoise, background removal, and style transfer. Running those steps on a dedicated NPU is the difference between an AI feature that runs seamlessly in the background and one that spikes CPU power and drains battery life.

In terms of efficiency, Qualcomm claims a 35% single-core uplift over the prior generation while using 43% less power. If those gains translate to shipping laptops, they will make room for sustained bursts of interactive work without forcing creators to choose between performance and unplugged runtime.

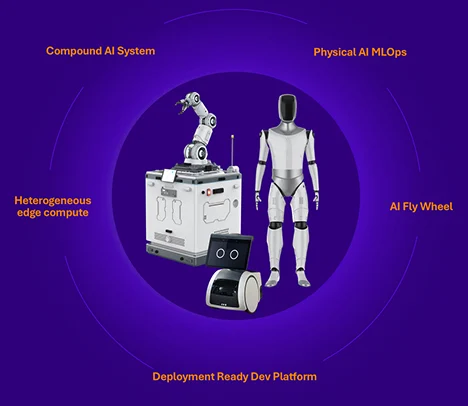

Dragonwing IQ10 Robotics Stack Architecture

As for robotics, Qualcomm introduced what it calls a comprehensive-stack robotics architecture that combines hardware, software, and “compound AI.” The company positions this architecture as a path from lab-grade prototypes to deployment-ready machines. At its core is the Dragonwing IQ10 series, described as a premium-tier robotics processor for industrial autonomous mobile robots and advanced full-size humanoids.

What stands out is the emphasis on end-to-end system behavior, with Qualcomm leaning into “mixed-criticality” design language and safety-grade, low-latency foundations—a nod to the messy reality of robots.

Perception networks can be heavy and bursty, but control loops and safety behaviors have hard deadlines. A platform that can schedule and isolate those classes of work cleanly reduces the need for external supervisory controllers and custom safety partitions, which is often where robotics programs bog down.

The Dragonwing IQ10 series is Qualcomm's latest addition to premium-tier robotics processors for humanoids and advanced autonomous mobile robots (AMRs).

Qualcomm also highlights support for end-to-end AI models, including vision-language-action and vision-language models for manipulation and human-robot interaction. The architecture also includes teleoperation tooling and an “AI data flywheel” concept for continuous improvement. The takeaway here is that signal acquisition is a must-have because a robot platform is only as good as its ability to ingest sensor streams, label and learn from real-world edge cases, and reliably roll out updated behaviors.

Qualcomm’s stack, tools, and partner ecosystem ultimately reduce the amount of bespoke infrastructure each robotics maker has to assemble to do that at scale.

Leapmotor’s Dual-Elite Controller and Snapdragon Digital Chassis

In its mobility update, Qualcomm said Snapdragon Cockpit and Ride Elite have now reached 10 programs across automakers, including Li Auto, Leapmotor, Zeekr, Great Wall Motor, NIO, and Chery. Ride Flex is already deployed in mass-produced vehicles across eight global programs, with the appeal being consolidation: one commercialized SoC that can host both infotainment and driver-assistance functions without splitting them across separate domains.

Leapmotor’s D19 is the most obvious example of what that consolidation looks like in hardware. The company is calling it the first mass-production vehicle built around a central domain controller based on dual Snapdragon Elite (SA8797P) platforms, combining cockpit, driver assistance, body controls, and the vehicle gateway. Instead of multiple compute islands with their own software stacks and update timelines, the D19 puts a larger share of the car’s core functions behind one centralized controller.

Snapdragon Digital Chassis is a technology portfolio that advances agentic AI in the automotive environment.

Qualcomm and Leapmotor also put hard numbers on the controller’s scope. The cockpit side supports up to eight displays, including multiple 3K and 4K panels, plus up to 18-channel audio. The driver-assistance configuration is designed for up to 13 cameras alongside LiDAR, millimeter-wave radar, ultrasonic sensors, and a high-precision IMU, targeting L2 capability with more than 30 features, including parking-to-parking. Leapmotor’s service-oriented architecture is described as exposing more than 200 modular capabilities, an explicit attempt to make the system legible to developers as a software surface rather than a sealed ECU.

Qualcomm also used CES to unveil supporting building blocks that reduce the number of add-ons around the main platforms. The company introduced its A10 5G Modem-RF, described as the industry’s first automotive 5G RedCap modem, and highlighted a V2X collaboration aimed at improving detection of non-line-of-sight hazards. Those pieces are less headline-worthy than a dual-chip controller, but they reinforce tighter integration, fewer external modules, and more vehicle functions living inside a power- and thermally-managed compute and connectivity stack.