Sound-Powered Sensors Open Another Avenue to Eliminate Batteries

A new metamaterial-based sensor harvests the vibration energy from sound waves to monitor buildings, earthquakes, or even medical devices—all without batteries.

ETH Zurich has developed a new metamaterial power source that converts sound wave vibrations into enough power to operate a device.

The new metamaterial does more than just create small amounts of electric current. It also uses the mechanical characteristics of the material to enact a certain amount of analog processing on the received signal.

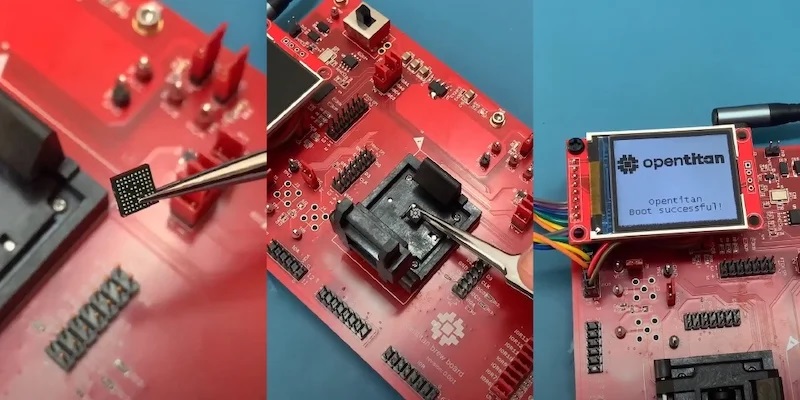

.jpg)

Mechanical tuning for specific sound recognition.

The newest versions of the thumbnail-sized sensor can distinguish between a dozen different words to derive sound energy. As an example, ETH Zurich researchers pointed out that simple words, like the spoken words “four” and “three,” come with different amounts and intensities of sound energy. “Four” has more energy than “three,” and the sensor can be mechanically tuned to recognize and only produce an electric current when hearing the word “four” and not “three.”

A Step Toward Always-On Computing

Today, we are surrounded by always-on computing systems such as smart homes, phones, and appliances that wait for keywords and trigger sounds. In a typical always-listening scenario, the device sleeps until it detects a sound or visual cue. The device then powers up enough to interpret the cue and decide if the cue is a command. While this process requires less power than if it were constantly on, it still requires substantial power for interpretation. In an area with a lot of ambient noise, the interpretation mode can be frequently triggered. Designers must then turn down the sensitivity and risk missing legitimate cues or employ a larger battery.

Zero-power technology mitigates that issue by interpreting sounds in the sensor material using tuned metamaterial. The metamaterial only creates an electrical current if the cue sound matches a desired trigger, eliminating the need for power-up interpretation computing.

Because the material is tuned during manufacturing, however, it can’t be later upgraded with new software for new trigger cues in the field.

ETH Zurich Creates a Tuned Metamaterial

ETH Zurich's new sensor is comprised of a mechanical network of vibrating elements, called a phononic resonator, also referred to as a mechanical neural network. The individual network elements are coupled, so they respond to specific audio events and recognize command words. When the right combination of elements is triggered, the device creates a small electric charge.

.jpg)

Prototype of phononic resonating sensor.

Each element is like a micro-tuning fork. Tuning forks vibrate when exposed to their resonant frequency. The tuning forks are mechanically connected such that if an undesired sound comes in, the vibrations will cancel each other out. If the desired sound comes in, the vibrations will complement each other. With enough elements vibrating in complement, a piezo material is stimulated to generate a charge that triggers the host computer to come out of deep sleep and act on the command. No external power is required for the sensor or the mechanical neural network to interpret the sound.

For Small, Low-Access Applications

In addition to sound interpretation, the metamaterial can also be formed to detect pressure and temperature patterns. This opens up even more applications in remote monitoring and implanted medical devices.

While there are numerous potential applications for such a sensor, devices where small size and power self-sufficiency are paramount will benefit the most. One example might be medical microsensors, like an eye pressure monitor, where there isn’t room for an external power source. Such a monitor could be small enough to not inhibit eye movement and, through the mechanical computing methodology, deliver information without external power.

Co-inventor Marc Serra-Garcia has brought the technology to AMOLF, a Netherlands-based public research institute, to refine the sensor technology. He and his team aim to have a solid prototype available to the industry by 2027.

.jpg)