The new series of dual-output Hall latches allows system designers to measure both speed and direction using a single integrated chip.

Novosense recently unveiled its MT73xx series of 3D dual-output Hall latches, addressing the growing demand for reliable motor control in modern vehicles. As cars integrate more electrified comfort and convenience features, the need for robust sensing solutions has never been greater.

The MT73XX-OXX series.

Full Integration Reduces Hassle for System Designers

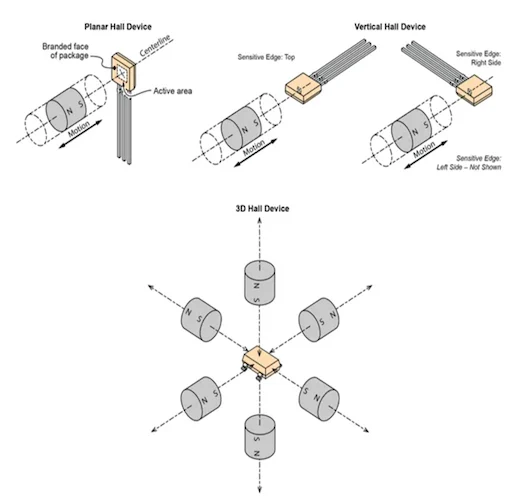

Novosense built the MT73xx family around a 3D Hall-effect structure that simplifies how designers handle motor control and measurement. Instead of relying on two separate latches placed at precise offsets, the device can generate both signals internally. Conventional Hall latches are usually mounted in pairs around a magnetic ring spaced 90 degrees apart. One sensor can only provide pulse frequency for speed, while the second device creates the phase shift needed to determine direction. This setup works, but it requires precise alignment and increases system complexity.

Conventional Hall-effect devices are activated by the motion of a magnet in relation to the plane and centerline of the active area of the device.

The MT73xx takes a different approach by using a 3D Hall structure inside a single chip, generating those two orthogonal (perpendicular) signals internally. The result is the same speed and direction information without the need for dual sensors or precise placement. Depending on the application, it can output two speed channels (SS mode) or a speed plus direction channel (SD mode). In this way, phase errors that normally appear when magnets or sensors are incorrectly aligned are mitigated.

The Vertical Hall Sensor Approach

A second key feature is Novosense's Vertical Hall Sensor (VHS) approach. By combining horizontal and vertical Hall elements, the chip can sense magnetic fields along multiple planes: XY, YZ, or XZ. This means it works with a wide mix of magnetic ring designs, whether axial, radial, or even non-standard geometries. For engineers, this flexibility opens the door to using more cost-effective magnets and reduces the need for ultra-precise mechanical setups.

A sensor that only supports one orientation limits design flexibility and can force engineers into higher-cost or less-efficient solutions. By supporting a wide range of ring configurations through its 3D and VHS sensing, the MT73xx series allows engineers to adapt the same device across multiple platforms without redesigning the system layout.

The device is also tough enough for demanding automotive environments. It’s rated to AEC-Q100 Automotive Grade 0, covering junction temperatures from -40°C up to +150°C. By rolling multiple outputs into one package, the MT73xx also helps shrink system complexity. Fewer sensors mean a smaller PCB footprint, less wiring, and a lower bill of materials. For OEMs, that translates into faster design cycles, fewer calibration steps, and more consistent performance when the design scales to production.

Competing Hall-Effect Circuits May Lack Integration

Novosense is stepping into a space already filled with established suppliers like Texas Instruments, Infineon, and Melexis. These companies also make Hall sensors that can handle speed and direction, but most still rely on using two separate devices or more complicated layouts to get the job done.

The MT73xx takes a different approach by building 3D sensing right into one chip. That means engineers don’t have to worry as much about alignment or extra parts, which can save time and cost during design. At the same time, the device is rated to Automotive Grade 0, so it holds its own against bigger competitors when it comes to reliability. Novosense is offering a cleaner, simpler option that still meets tough automotive standards, making it an attractive choice for high-volume systems where every component counts.