The Evergreen Vento FCM33 delivers modular 33 kW shelves with over 95% efficiency for semiconductor and industrial DC power systems.

Power density and reliability are everything in semiconductor testing. As chip complexity grows, so do the demands on test equipment, particularly in high-power burn-in environments where precision and uptime mean the difference between yield and waste. Engineers are finding that traditional AC-DC power systems simply can’t keep up with the rapid scaling of today’s semiconductor fabrication and validation lines.

Advanced Energy Industries may have found a fix. The Evergreen Vento FCM33 power shelf delivers 33 kW of modular, high-density power conversion in a single 1U rackmount form factor. Designed for semiconductor IC test systems, component burn-in, and other high-power industrial DC applications, the unit combines over 95% efficiency with digital system-level control. It’s not just about cramming more power into less space—it’s about doing so with the precision and resilience the semiconductor industry demands.

The Evergreen FCM 33kW, 1U Shelf AC-DC Power converter. Image used courtesy of Advanced Energy

Compact Power With Scalable Intelligence

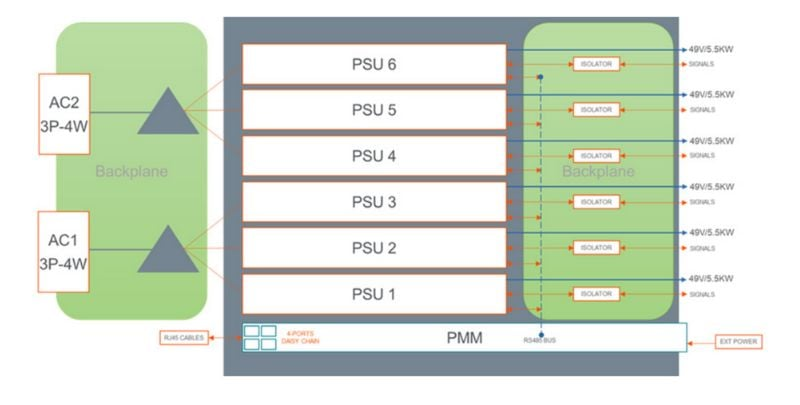

At just 1.81 inches tall, the Evergreen Vento FCM33 packs six independent 5.5 kW modules into a single shelf. Each output delivers 49 VDC, producing a 33 kW capacity at >95% efficiency. That’s roughly 32 W per cubic inch, which is important for data center standards that inspired its design. For engineers building or upgrading multi-kilowatt systems, this means greater flexibility and less space consumption per test rack.

The system’s modular design is built for growth. It incorporates multiple shelves that can be paralleled to reach megawatt-scale output without complex rewiring. Hot-swappable modules allow operators to replace or service power units on the fly, reducing downtime and maintenance costs. Dual input feeds and a robust MTBF/MTTR balance further enhance uptime, ensuring test benches keep running even under the most demanding production schedules.

Engineered for Global Test Environments

Power quality isn’t the same everywhere, making it tricky to deploy test systems across different regions. The FCM33 runs reliably from 208 to 230 VAC and stays steady even when the supply dips to around 200 V. In other words, it doesn’t mind a little fluctuation. Test setups can keep running without hiccups or adding extra line conditioning gear.

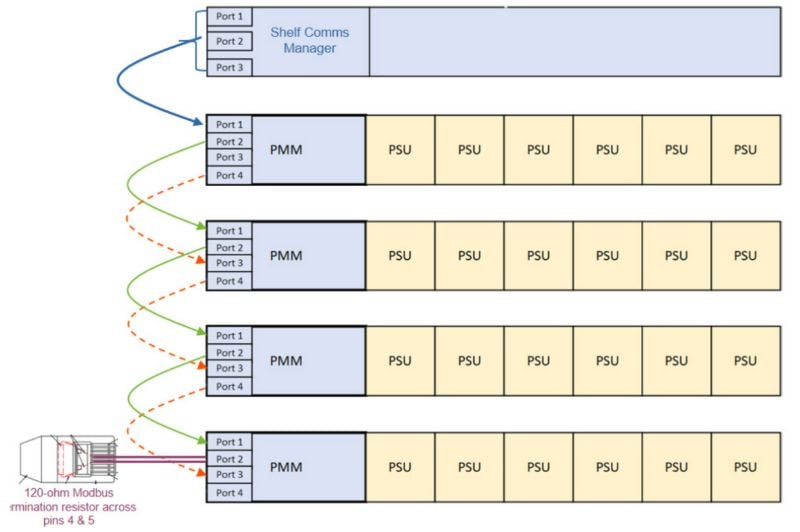

The RJ45 interface can be used for communication between shelves and management system. Image used courtesy of Advanced Energy

The system also has built-in RS-485 communication and digital rack-level control, enabling precise monitoring and configuration, allowing operators to automate voltage adjustments, log performance data, or integrate the unit into existing facility-wide energy management systems.

Smarter Power for a Power-Hungry Future

Manufacturers are testing more chips simultaneously to speed up production, which puts steady pressure on power systems to keep up. Advanced Energy’s modular design handles that pretty well, and it combines small power modules with built-in digital control, so setups can scale as needed and keep delivering stable power even when loads start to shift.

The FCM33 can accommodate up to six PSUs. Diagram courtesy of Advanced Energy

Beyond semiconductors, the FCM33’s power density and thermal characteristics are useful for broader industrial DC applications, from automated test equipment to industrial laser drivers or electric-mobility infrastructure. With energy efficiency regulations tightening worldwide, products that squeeze more usable power from each watt are bound to see wider adoption.

Power delivery may not get much attention compared to chips or circuits, but it often keeps production moving. With the FCM33, Advanced Energy takes a familiar approach when looking at shrinking size, boosting efficiency, and giving engineers some extra control. It makes sense for test labs and industrial setups that are always running out of rack space but still need more power. The design aligns with how modern manufacturing works by scaling up performance without rebuilding the whole setup.